tear strength test for rubber|vulcanized rubber tear test : China 3.2.1 Type A tear strength—the maximum force required to cause a nick or cut in a Type A (nicked crescent) test piece to grow by tearing the rubber, divided by the thickness of the test . Confira a seguir algumas das principais datas de 2024. Semestre 2024/1 - Início em 4 de março e término em 13 de julho. Solicitação de matrícula em CCR (antiga rematrícula) .

{plog:ftitle_list}

Resultado da EA Sports FC 24 v1.7.4. In EA Sports FC 24, players have the opportunity to immerse themselves in the world of professional football like never before. .

vulcanized tear resistance test

The tear strength of thermoset rubbers, thermoplastic elastomers, and silicones can be measured according to specification ASTM D624. The test measures the strength required to initiate a .

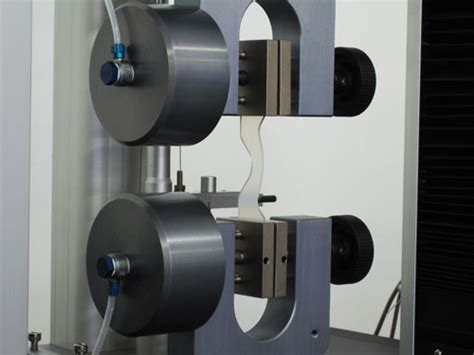

This shows a tear strength test appropriate for rubbers, elastomers, and silicones, and performed according to ASTM D624 on an ADMET universal testing machine.

5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method .3.2.1 Type A tear strength—the maximum force required to cause a nick or cut in a Type A (nicked crescent) test piece to grow by tearing the rubber, divided by the thickness of the test .

This test method is used to evaluate the tear strength of common vulcanized rubbers and thermoplastic elastomers. Tear strength can be influenced by mechanical fibering (surface .ISO 34-1 is a testing standard for measuring the tear strength of vulcanized or thermoplastic rubbers. Method A outlines the test procedure using a trouser test piece, method B using an angle test piece, and method C using a crescent .ASTM D624-00(2020): Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers. Application: Utilized for determining tear strength in vulcanized rubber and thermoplastic elastomers.ASTM D624 is a testing standard for measuring the tear strength of thermoset rubbers, thermoplastic elastomers, and silicones. This standard describes multiple different types of sample shapes (Type A, B, C, T, and CP) that can .

vulcanized rubber tear test

ASTM D624 Tear Strength Test Template About TestSuite™ TW To simplify testing to ASTM D624, MTS has developed a TestSuite TW test template that will create and report all of the critical tear strength test data prescribed by the standard. There are several specimen types that can be used, including Test Type A, B, C, T, and CP. more indicative of tensile strength than tear strength. 4.2.4 Type T, a trouser tear test piece, as shown in Fig. 2 . Type T measures tear propagation in a direction parallel to the length of both legs. 4.2.5 Type CP, a test piece described in Fig. 3 , which is a modiÞed trouser tear test piece with a constrained path for the tear.ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test.

The tear strength of a material is a compound property of the force require to initiate a tear in the material and the force required to propagate the tear. Tear tests are performed similarly to common tensile tests for rubber. Related Standards. ISO 34, ASTM D624. IntroductionThe value of tear strength obtained depends on the shape of the test piece, speed of stretching, and temperature of test. It can also be susceptible to grain effects in rubber. NOTE A separate method for the determination of the tear strength of small test pieces of rubber (Delft test pieces) is specified in ISO 34-2.MTS test systems and solutions for testing to ASTM D624: Tear Strength of Vulcanized Rubber and Thermoplastic Elastomers (TPE) . Learn more. MTS provides testing systems, mechanical testing systems, simulation systems and sensing solutions to researchers, developers and manufacturers worldwide.

— method C, using a crescent test piece with a nick. The value of tear strength obtained depends on the shape of the test piece, speed of stretching, and temperature of test. It can also be susceptible to grain effects in rubber. NOTE A separate method for the determination of the tear strength of small test pieces of rubber (Delft test

Tear strength is the tensile force required to rupture a pre-slit woven fabric sample under controlled conditions. Edge tearing strength of paper is the load required to tear a sample over a V-notch fixture. Typical graph showing a tear strength test: We provide force measurement instruments and materials testing machines for tear strength testing. Significance and Use 5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method measures the resistance to tearing action. 5.2 Tear strISO 34-1 is a testing standard for measuring the tear strength of vulcanized or thermoplastic rubbers. This standard describes three different test methods based on specimen geometry as the value of tear strength obtained depends on the shape of the test specimen in addition to the testing speed and temperature.

ISO 34-1:2010 specifies three test methods for the determination of the tear strength of vulcanized or thermoplastic rubber, namely: method A, using a trouser test piece; method B, using an angle test piece, with or without a nick of specified depth; method C, using a crescent test piece with a nick. The value of tear strength obtained depends .ASTM D624 | Plastics and Elastomers | Tension Testing. ASTM D624 is a testing standard for measuring the tear strength of thermoset rubbers, thermoplastic elastomers, and silicones. This standard describes multiple different types of sample shapes (Type A, B, C, T, and CP) that can be tested in a standard universal testing machine.

NOTE A separate method for the determination of the tear strength of small test pieces of rubber (Delft test pieces) is specified in ISO 34-2. 2 Normative references. The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the . Tear strength testing is therefore considered a qualitative test to demonstrate failure mode rather than a value comparative test to allow precise comparisons of various materials. . Tear Strength of Rubber. The values for various rubber materials are: natural rubber (23.95 +/-1.85 kN/m), nitrile rubber (9.14 +/-1.54 kN/m), styrene-butadiene .

3.2.3 Die B (nicked tab end) tear strength—the maximum force required to cause a nick or cut in the specified crescent-shaped test piece with tab ends to grow by tearing of the rubber, divided by the thickness of the test piece. 3.2.4 Die C tear strength—the maximum force required to cause a rupture by tearing action of the right angle test

vulcanized rubber tear strength

Testing Tips and Tricks. ISO 34 provides similar results to ASTM D624, another common test that measures the tear strength of elastomeric materials.Though the ASTM and ISO organizations are currently working toward diminishing the .The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress .ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test.grow by tearing the rubber, divided by the thickness of the test piece. 3.2.3 Type C tear strength—the maximum force required to cause a rupture of a Type C (right angle) test piece, divided by the thickness of the test piece. 3.2.4 Type T or trouser tear strength—the mean or median force, calculated in accordance with procedures in this .

Tear strength indicates the force a rubber material can still withstand after the material is damaged. . This test involves exposing the rubber test material to a rotating drum covered with abrasive paper. After being exposed to exactly 40 metres of abrasive paper, the volume of wear in mm3 is measured. .Tear tests were performed, and the specimens were evaluated with respect to tear strength, one of their basic mechanical properties. . in rubber tear tests, it is necessary to use pneumatic parallel grippers, pantograph grips, eccentric roller type grips, Henry Scott type grips, or other grips equipped with this feature. Measurement Results .test piece, the force acting in a direction substantially along the length of the test piece 3.3 nicked angle tear strength crescent tear strength maximum force required to cause a nick cut in a specified angle- or crescent-shaped test piece to extend by tearing of the rubber, divided by the thickness of the test piece, the force acting in a .ASTM D5884 – Standard Test Method for Determining Tearing Strength of Internally Reinforced Geomembranes; ASTM D624 – Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers; Get help with your tear strength testing set up. If you need some help making sure that you’re getting the kind of .

For the tensile test on rubber and elastomers, ASTM D412 specifies six types of dumbbell specimens and two types of cut ring specimens.; The most commonly used specimen is a C-shape dumbbell specimen (ASTM D412 Type C) with an overall length of 115 mm (4.5 inches), gauge length of 25 mm (1 inch), measurement width of 6 mm (0.25 inches) and thickness of 3 .

From cure curves to compression set, this complete guide covers all the essential rubber testing methods you need to know. Perfect for anyone in the rubber industry. . Mechanical Testing: Cured Rubber: Tensile Strength: Tensile Tester: Mechanical Testing: Cured Rubber: ASTM D412: Flex Fatigue: DeMattia Flex Tester: Mechanical Testing: Cured . Physical Testing of Rubber Part A3: Method for Determination of Tear Strength, (Trouser, Angle and Crescent Test Pieces) Specifies three methods. Method A uses a trouser shaped test piece; method B uses an angle test piece and . How to Test Tear Resistance Tear resistance is tested on a tensometer in the same manner as the tensile strength test except the specimen is one of 5 specific shapes: Type A, B, C, T or CP. A graph is produced in the same manner as the stress-strain curve except the Tear Strength graph is force over jaw separation length.

thermoplastic rubber tear strength

compression test graph

Porto Belo - SC Mulheres Homens Trans Novidade . Yara Ri.

tear strength test for rubber|vulcanized rubber tear test